In modern manufacturing, the standardization of equipment maintenance directly affects production efficiency and operating costs. Traditional equipment maintenance relies mainly on technicians' personal experience and paper documents, facing pain points such as inconsistent standard execution and difficulty in unifying operating procedures. 3D animation technology, with its unique visualization advantages, is providing innovative solutions for the standardization of mechanical equipment maintenance.

Establishment of Visualized Operating Procedures

The primary task of equipment maintenance standardization is to establish clear and unified operating procedures. 3D animation, through precise equipment modeling and dynamic demonstration, transforms abstract maintenance requirements into intuitive visual guidance. Compared to traditional 2D drawings, 3D animation can display maintenance details from multiple angles, ensuring that every technician can accurately understand and execute unified standards.

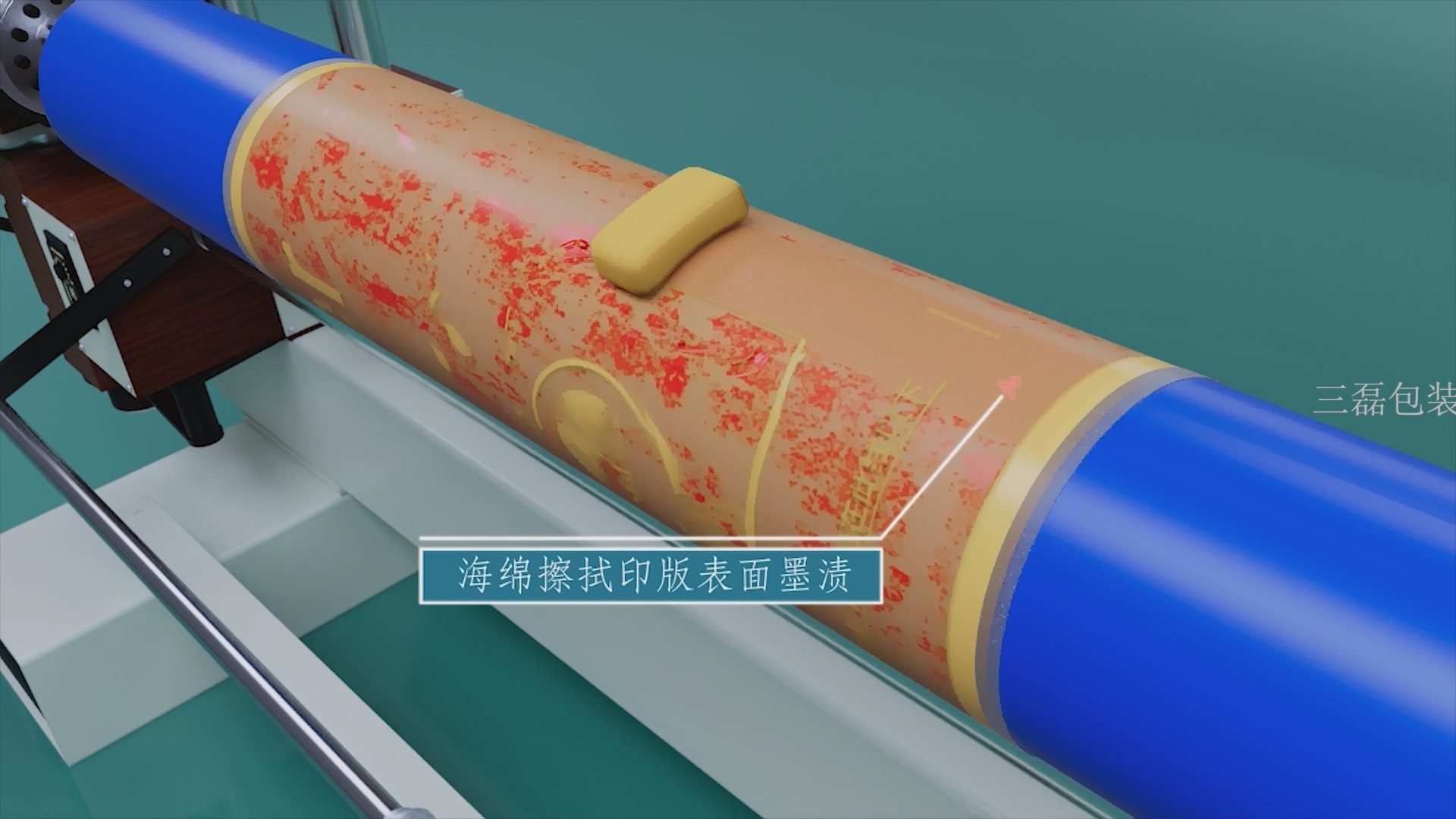

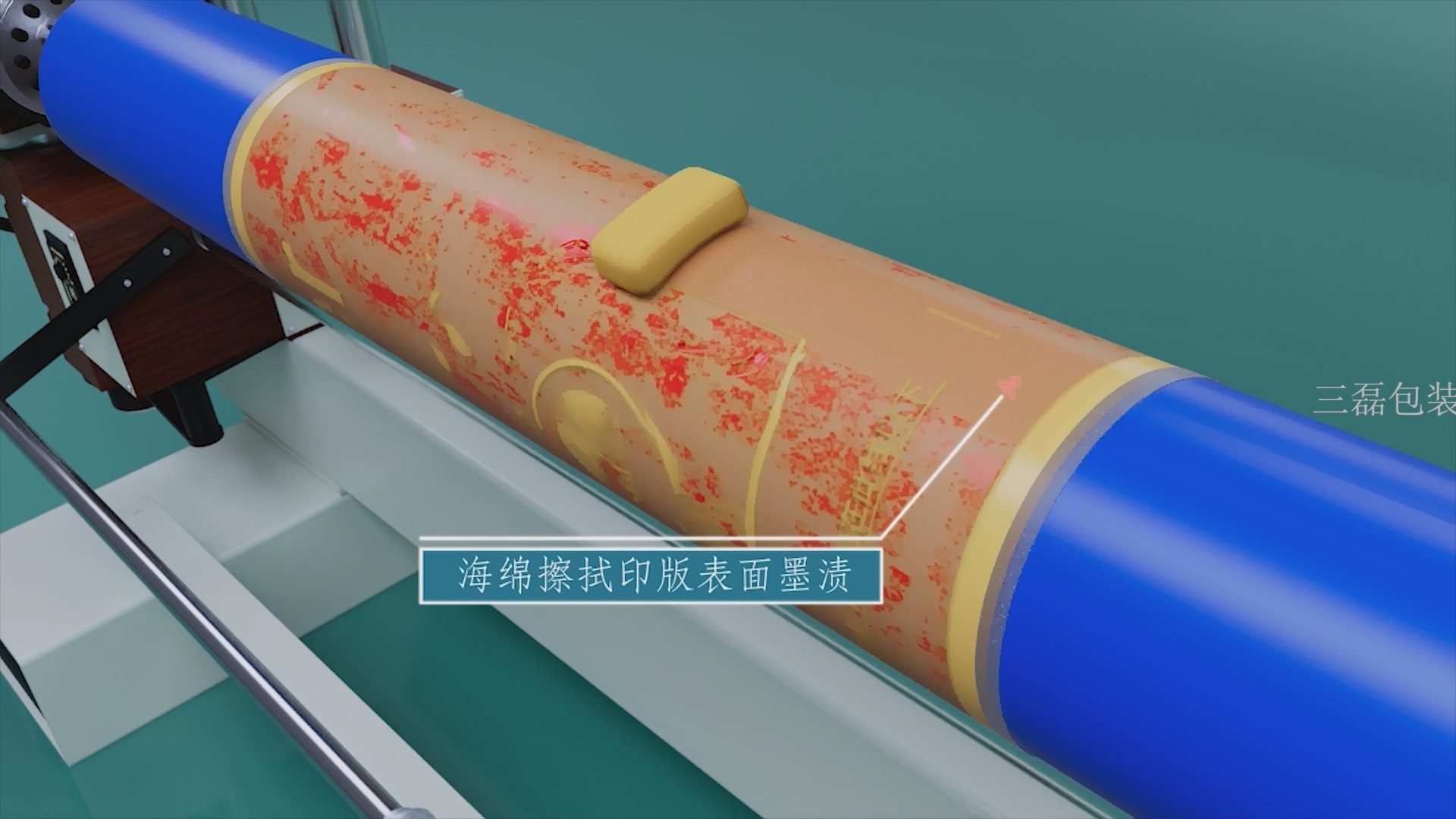

In the practice of Guangdong Topin Intelligent Machinery Technology Co., Ltd., the maintenance animation for the ink printing press detailed the entire process from daily cleaning to regular maintenance. The animation not only clarified the operating steps for each maintenance phase but also highlighted key maintenance points for critical components through close-ups and slow-motion demonstrations. This visual guidance enables technicians of varying skill levels to perform maintenance tasks according to unified standards, significantly improving the consistency of maintenance quality.

Building a Preventive Maintenance System

The core of equipment maintenance standardization lies in shifting from reactive repair to proactive prevention. 3D animation, by demonstrating equipment operating mechanisms and wear patterns, helps technicians develop awareness and capability for preventive maintenance. The animation can clearly present the service life cycle of key equipment components, warn of potential failure risks, and guide technicians in timely preventive maintenance.

The practice of Shenzhen Wander Digital Technology Co., Ltd. shows that a preventive maintenance system based on 3D animation has significantly reduced the rate of unexpected equipment failures. Through animation guidance, technicians can accurately grasp the timing for maintenance of various components, avoiding resource waste from over-maintenance and preventing equipment failures caused by insufficient maintenance. This preventive maintenance model has led to a significant improvement in overall equipment efficiency.

Precise Control of Maintenance Processes

3D animation technology provides an effective tool for achieving precise control of maintenance processes. By integrating elements such as maintenance standards, operating procedures, and quality requirements into the animation system, enterprises can establish a comprehensive maintenance management database. This system not only guides on-site operations but also enables traceability, evaluation, and optimization of the maintenance process.

In the practical application at Xiamen Sanlei Enterprise, technicians learn maintenance standards and perform maintenance tasks through the animation system, recording maintenance status. Management personnel can monitor maintenance progress and quality in real-time through the system, promptly identifying and resolving issues. This precise management method enhances supervision of the maintenance process and provides a basis for continuous improvement.

Systematic Inheritance of Knowledge Management

Continuous improvement of equipment maintenance levels requires the establishment of effective knowledge inheritance mechanisms. 3D animation, by transforming individual experience and best practices into standardized visual content, achieves systematic accumulation and inheritance of maintenance knowledge. This knowledge management approach preserves the valuable experience of senior technicians while providing an effective path for the rapid growth of new employees.

The case of Foshan Jinbing Machinery Co., Ltd. shows that the maintenance knowledge system established through 3D animation enables new employees to grasp key equipment maintenance points in a shorter period. The systematic training content ensures the accuracy and consistency of technical inheritance, fostering a sustainable technical service team for the enterprise. This innovation in knowledge management has continuously elevated the company's maintenance standards.

Positive Cycle of Continuous Improvement

3D animation technology provides an effective platform for the continuous improvement of equipment maintenance. By recording and analyzing data and cases from the maintenance process, enterprises can continuously identify shortcomings in maintenance standards and promptly optimize and improve them. This continuous improvement mechanism ensures the ongoing enhancement of the company's maintenance standardization level.

During implementation, enterprises can promptly translate best practices summarized from maintenance practices into 3D animation content, updating and refining maintenance standards. Simultaneously, technicians can provide feedback on issues and suggestions encountered during maintenance practices through the animation system, forming a positively interactive improvement cycle. This mechanism of continuous improvement ensures that the company's equipment maintenance work always remains at an advanced level.

Significant Improvement in Cost-Effectiveness

From an input-output perspective, the application of 3D animation in equipment maintenance standardization shows significant economic benefits. Although initial investment in animation production is required, in the long run, a standardized maintenance system leads to cost savings in multiple aspects, including reduced maintenance costs, extended equipment lifespan, and increased production efficiency.

Data from Xiamen Sanlei Enterprise indicates that after implementing a standardized maintenance system based on 3D animation, annual maintenance costs decreased by 25%, the average time between equipment failures increased by 30%, and overall equipment efficiency improved by 20%. These improvements directly translate into economic benefits and competitive advantages for the company.

3D animation technology, through dimensions such as establishing visualized procedures, building preventive systems, and precise process management, offers innovative solutions for the standardization of mechanical equipment maintenance. This technological application not only enhances the efficiency and quality of maintenance work but, more importantly, establishes a standardized system for continuous improvement. With the continuous development of technology and deeper application, 3D animation will undoubtedly play an even more significant role in the field of equipment maintenance.

Selected FAQs:

Q: Will operating and maintenance animations expose sensitive equipment structures?

A: No.

Operating and maintenance animations demonstrate the content of traditional paper operation manuals in the form of video animations (e.g., in printing presses, the feeding unit mainly explains how to adjust baffles and guides, and how to feed materials; the printing unit mainly explains how to apply ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Mechanical factories can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always rests with the mechanical factory.

Q: Are operating and maintenance animations very expensive?

A: First, the conclusion: Equipment operating and maintenance animations create value for mechanical factories. The greater the investment, the greater the return.

The production cost for equipment operating and maintenance animations generally ranges from tens of thousands to hundreds of thousands, or even higher. While seemingly expensive on the surface, the actual average cost per piece of equipment is not high.

How do equipment operating and maintenance animations create value for mechanical factories?

1. Low amortization cost: Machine equipment is generally updated slightly every 2 years and significantly every 4 years. The total cost of animation production amortized per machine is very low;

2. Equipment premium: According to actual test data from mechanical factories, for every 1 yuan invested in producing equipment operating and maintenance animations, the resulting equipment sales premium is about 3-5 yuan (i.e., 3-5 times);

3. Significantly reduce after-sales service costs, especially during the equipment warranty period;

4. Effectively improve customer loyalty;

5. More competitive compared to similar products.

Characteristics: Large initial investment, very small subsequent investment.

Q: How should equipment factories with many single-product types produce operating and maintenance animations?

A: Generally, equipment with many single-product types is not priced high (thousands to tens of thousands of yuan). For this type of equipment, consider the following solutions for producing operating and maintenance animations:

1. Produce on a turnkey basis. This is conducive to unified image and provides advantages in price negotiation;

2. Consider combining 3D animation with live-action filming to reduce production costs;

3. Produce operating and maintenance animations separately for flagship or high-value-added products to highlight their superior class compared to competitors.

About Xuncheng Technology

Founded in 2016, with 9 years of professional experience in industrial 3D animation creation, serving clients ranging from startups, overseas clients, listed companies, to foreign-invested enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animations. This not only brings a unique visual experience to clients but also quickly touches their hearts.